Vacuum Composite Supplies

Everything you need for successful vacuum bagging/ resin infusion including vacuum consumables, core materials, equipment and even kits with all the materials you'll need.

See our guide to Wet Lay up with Vacuum Bagging here

See here for our huge range of composites fabrics including kevlar, aramid, hybrids and more.

See here for our Carbon Fibre As always our tech advisors are on hand with free friendly advice should you need it - contact us here.

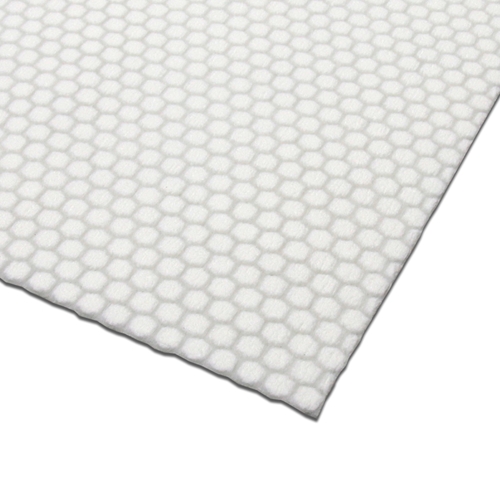

Resin infusion, also known as vacuum infusion, is an advanced composite manufacturing process widely used in the production of high-performance, lightweight structures. This method employs a vacuum to drive resin into a dry fibre layup within a mould. The process starts with the dry fibres, typically fibreglass, carbon fibre, or Kevlar, being laid into the mould. A peel ply and perforated release film are often placed on top of the fibres, followed by a breather fabric and the vacuum bag. Once sealed, the vacuum is applied, removing air from the laminate and compacting the fibres.

The next step in resin infusion involves carefully introducing the resin into the mould. A resin feed line allows the mixed resin to be drawn into the laminate under the influence of the vacuum. This controlled process ensures a consistent resin-to-fibre ratio, essential for achieving optimal mechanical properties in the final product. The vacuum ensures a tight consolidation of the laminate, minimizing voids and ensuring a high-quality, lightweight and strong composite part. This technique is especially beneficial in creating large or complex shapes where traditional wet layup methods might struggle with resin distribution and air entrapment. Resin infusion is widely adopted in industries such as aerospace, automotive, marine, and sports equipment manufacturing, where high-strength, lightweight components are crucial.